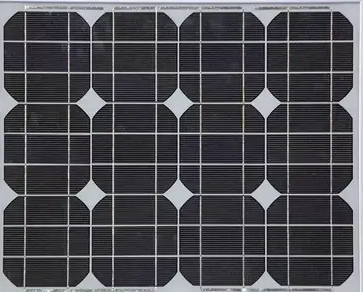

1. MONOCRYSTALLINE SOLAR PANELS

Because of their many advantages, monocrystalline solar panels are the most commonly used solar panels on the market today. Approximately 95% of solar cells sold today use silicon as the semiconductor material. Silicon is abundant, stable, non-toxic, and works well with established electric generation technologies.

Material: Pure Silicon

– 24.4% efficiency

– Longest lifespan

– 38.1 g CO2-eq/kWh

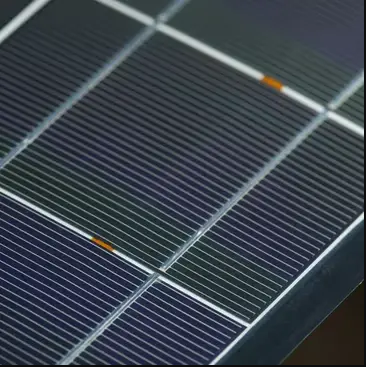

2. POLYCRYSTALLINE SOLAR PANELS

As the name implies, polycrystalline solar panels are made of cells formed from multiple, non-aligned silicon crystals. These first-generation solar cells are produced by melting solar-grade silicon, casting it into a mold, and allowing it to solidify. The molding silicon is then sliced into wafers to be used in a solar panel.

Material: Melted Silicon Crystals

– 19.9% efficiency

– Moderate lifespan

– 27.2g CO2-eq/kWh

3. THIN FILM

The high cost of producing solar-grade silicon led to the creation of several types of second and third-generation solar cells known as thin-film semiconductors. Thin-film solar cells need a lower volume of materials, often using a layer of silicon as little as one micron thick, which is about 1/300th of the width of mono- and polycrystalline solar cells. The silicon is also of lower quality than the kind used in monocrystalline.

Material: A Variety of Materials

– 18.9% efficiency

– Shortest lifespan

– As little as 21.4g CO2-eq/kWh